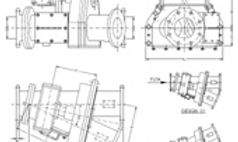

Diverter valve

Efficiency in flow control in pneumatic conveying

» Flow control to feed two possible destinations «

The design of this equipment allows for diverting powder or granulates from one source in pneumatic conveying lines to two different destinies, e.g., two different silos.

The valve is available with different nozzle diameters, so that it adjusts to different existing piping.

Flow interruptions and turbulences are avoided because of the narrow angle of divergence between the outlets of the valve connected to the piping.

Typical characteristics:

· For heavy duty service and abrasive products;

· Narrow angle of divergence;

· Available in 9 different sizes;

· Compact construction;

· Available with 3 types of drives: pneumatic, motorized and manual;

· High temperature applications.

In order to reduce friction and wear of the metal sheets and provide for an excellent transition of the movable parts, typically, a brass coating is used on the sliding gate of the valve.

Some advantages:

· Best cost-benefit ratio - Increase of productivity;

· The useful life of the sealing is assured by self-adjustable springs.

Whenever you need a conveying system, contact Zeppelin Systems Latin America, your reliable partner for success!

Divrter valve